Laser Controller Board CCD camera positioning laser cutting control system AWC7824

The CCD camera positioning laser cutting control system is a visual motion control system mainly developed for the camera positioning identification and cutting requirements that require higher precision It has the characteristics of high precision and high stability Mainly used in laser cutting trademark embroidery, camera cutting printing, camera cutting cloth and other visual positioning laser cutting equipment At the same time, the system can also be used as an ordinary laser motion control system

co2 laser controller board Model: AWC7824

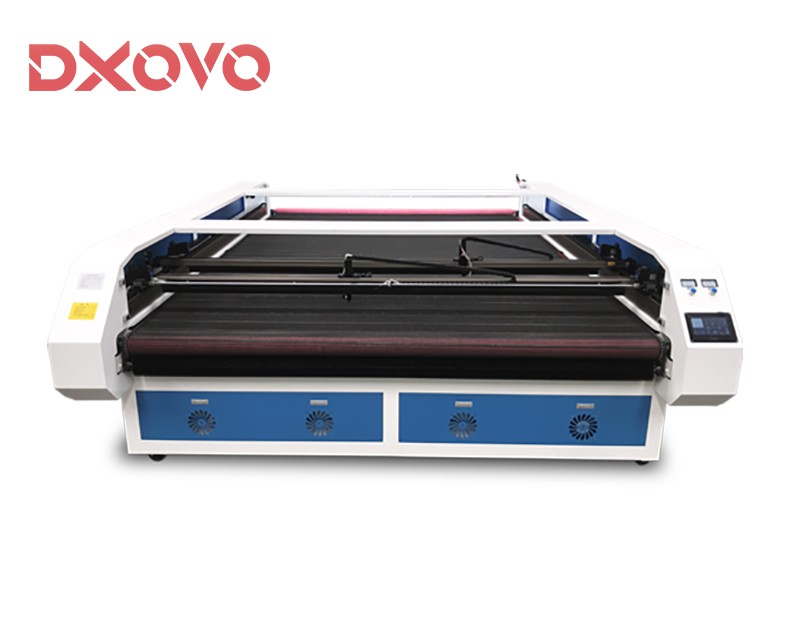

Application industry: widely used in laser and vibrating knife cutting equipment such as trademark cutting machine, advertising packaging equipment, leather goods cutting machine, etc. Applicable to clothing leather, trademark weaving, digital printing, textile embroidery, advertising packaging, cloth toys and other industries.

Product description

Features

Technical Parameters

|

Model |

AWC7824 |

|||

|

Supported Lasers |

CO2 glass laser / RF laser |

|||

|

Cutting accuracy |

±0.01mm |

|||

|

Number of control axis |

X,Y,Z,U axis |

|||

|

Automatic feeding function |

support |

|||

|

CCD Visual Recognition |

support |

|||

|

Control head |

Double-Head |

|||

|

Input |

6 Roads |

|||

|

Output |

8 Roads |

|||

|

Input voltage |

DC24V, 3A |

|||

|

Control Laser energy |

0-100%, 0.1% Continuously adjustable |

|||

|

Continuous cutting |

Support interrupted and then continue to cut |

|||

|

Compatible systems |

WinXP, Vista, Win7, Win8, Win10,win11 |

|||

|

Supported Graphics Formats |

G-code,AI,SVG,PDF,DXF,PLT,DST,DSB,UD5,BMP,JIF,JPG,PNG etc. |

|||

|

Compatible software |

LaserCAD, lightburn (plug-in support Coreldraw,Auto cad,Adobe Illustrator) |

|||

|

Communication port |

Support USB high-speed reading and network LAN port communication |

Solutions

Widely used in packaging, advertising, clothing, furniture, bags, footwear, automotive, aerospace, seal, energy, composite, etc.Typical Applications

The excellent performance of the machine is widely used in all walks of lifeContact Us

Business negotiation, looking for partners, Join Us.