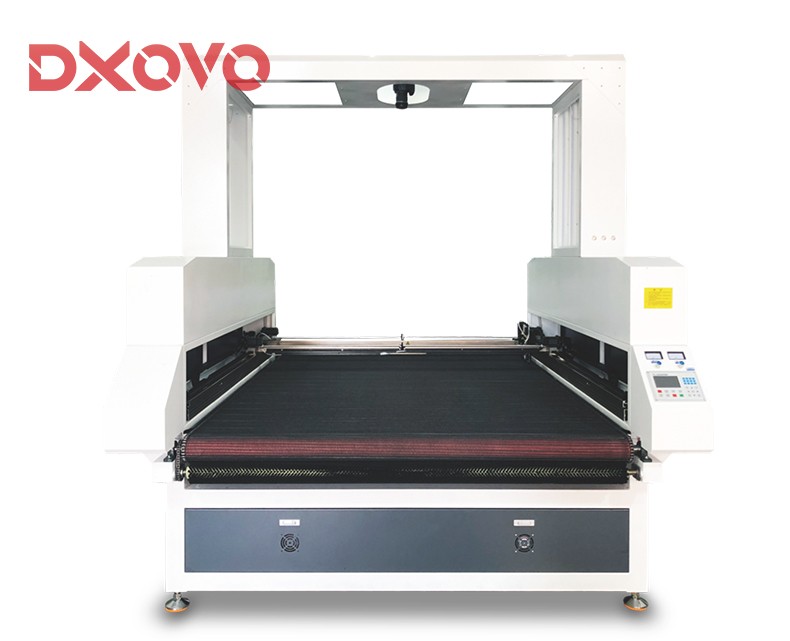

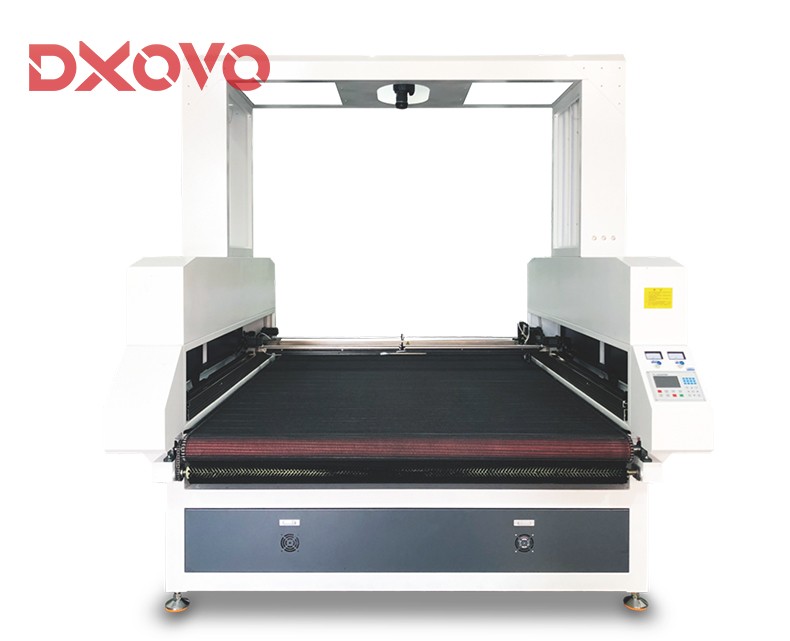

Digital Printing Laser Cutting Machine

The Digital Printing Laser Cutting Machine is suitable for the garment industry, thereby further reducing the pressure on enterprises

Digital Printing Laser Cutting Machine

Categorys : Industry Application

Sales hotline : +86 13725766389 Lucy Guo

Email : sales@dxovo.com

WhatsApp : +0086 13725766389

Fabrics suitable for digital thermal transfer printing:

Chiffon yarn, Oxford cloth, polyester cloth, polyester cotton cloth, etc.

Products suitable for digital thermal transfer printing:

T-shirts, advertising shirts, cultural shirts, dresses, sportswear, couple clothes, fashion underwear and other clothing.

The high-speed automatic digital printing laser cloth cutting machine adopts a high-resolution camera to realize one-time large-format multi-pattern high-precision imaging, avoiding errors caused by splicing images and image quality degradation. Multi-pattern feature flexible point positioning, multiple patterns jointly identify one-time cutting. The self-seeking frame corrects the easily deformed pattern, which perfectly solves the problems caused by material deformation and stretching. It is the ideal choice for modern high-speed automatic large-scale enterprises, and the development direction of personalized design.

The Digital Printing Laser Cutting Machine is suitable for the garment industry, thereby further reducing the pressure on enterprises.

The fully automatic CNC searching and cutting machine can save you 5 labors, and the processing speed is 2.5-3 times faster than the traditional one.

The camera positioning laser cutting machine has a relatively wide range of applications, not only for woven fabric embroidery pieces, but also for other non-metallic materials such as paper, wool, and leather with printed graphics.

Compared with traditional proofing methods, digital printing proofing has the following four advantages:

1. Fast response

With its fast proofing, the digital printing machine can improve the response speed of the enterprise to the order, one step ahead in the market, the competition of printing enterprises has intensified, the processing price has dropped, and the profit margin has decreased. Customers put forward higher requirements for printing companies in terms of cost, response speed, quality, and service. Whichever company produces samples first will be one step ahead and get orders. Improving the speed of proofing will undoubtedly enable enterprises to win among many competitors.

2. Cost reduction

Using the digital printing machine to make samples can replace part of the original work that must be done on the rotary screen and flat screen printing machines, without taking up machine time. Generally, it takes 3-4 hours for a machine to make a sample. If the customer is not satisfied, it will be revised repeatedly, resulting in a great waste of the production capacity of the enterprise.

3. The proofing effect is good, and the customer recognition rate is high

Digital printing and traditional printing belong to different systems. Many professional and technical personnel are worried that the proofing effect of digital printing machine is too good, and traditional printing cannot achieve such an effect. In fact, this kind of worry is unnecessary. At present, in order to solve this problem, domestic companies have organized the best craftsmen in China to conduct in-depth research and find out a solution. This solution uses software to adjust the proofing effect of digital printing, so that the traditional printing machine can fully achieve the proofing effect in production. From the perspective of color, since the color gamut of paste used in traditional printing is wider than that of digital printing ink, the color effect produced by digital printing machine can also be completely simulated by traditional paste.

4. Wide range of application

Inks that can be used for proofing include reactive inks, acid inks, and disperse inks (transfer printing). Direct printing with disperse inks is still looking for suitable inks. In the customer's sample, if it is a paper manuscript or an electronic manuscript, it can be directly proofed with a digital printing machine after color separation, and the traditional printing machine can complete mass production according to the proofing effect.

If the incoming sample is a cloth sample, it is necessary to explain some characteristics of digital printing to the customer, and the proofing mode can only be changed after the customer's approval. Enterprises should especially consider the ability of customers to accept new things. For some conservative customers, it is still relatively safe to use traditional proofing methods. Only when digital proofing becomes the mainstream of the market, it is appropriate to recommend digital printing proofing to these customers . This process will take about 2-3 years in China.

Digital printing technology and traditional printing technology are two completely different printing mechanisms in printing, so the use of digital printing machines for proofing requires a running-in period with customers. From the perspective of process links, the company's internal proofing and production systems also have a running-in period. If possible, it is best to formulate a set of process standards so that enterprises can quickly introduce digital printing proofing systems and be recognized by customers.

Solutions

Widely used in packaging, advertising, clothing, furniture, bags, footwear, automotive, aerospace, seal, energy, composite, etc.Contact Us

Business negotiation, looking for partners, Join Us.