How much is a digital printing machine?

Digital printing machines can print ink on objects of different materials, and at the same time, the time cost and actual cost of printing are much lower than traditional printing methods Digital printing machines also need regular maintenance and care, so as to improve the service life of the product So, how much is a digital printing machine?

Email : sales@dxovo.com

WhatsApp : +0086 13725766389

Digital printing machines can print ink on objects of different materials, and at the same time, the time cost and actual cost of printing are much lower than traditional printing methods. Digital printing machines also need regular maintenance and care, so as to improve the service life of the product. So, how much is a digital printing machine?

The price of a uv digital printing machine is around 100,000 to 300,000, and the price will increase several times if it is customized. The internal configuration of the uv digital printing machine is different, and the price also varies greatly. It is recommended to consult the manufacturer directly to obtain the actual price.

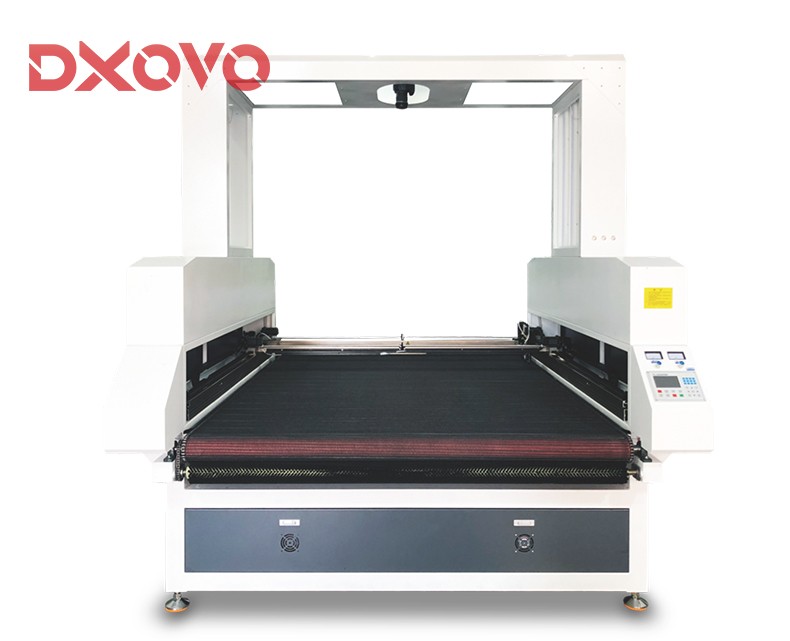

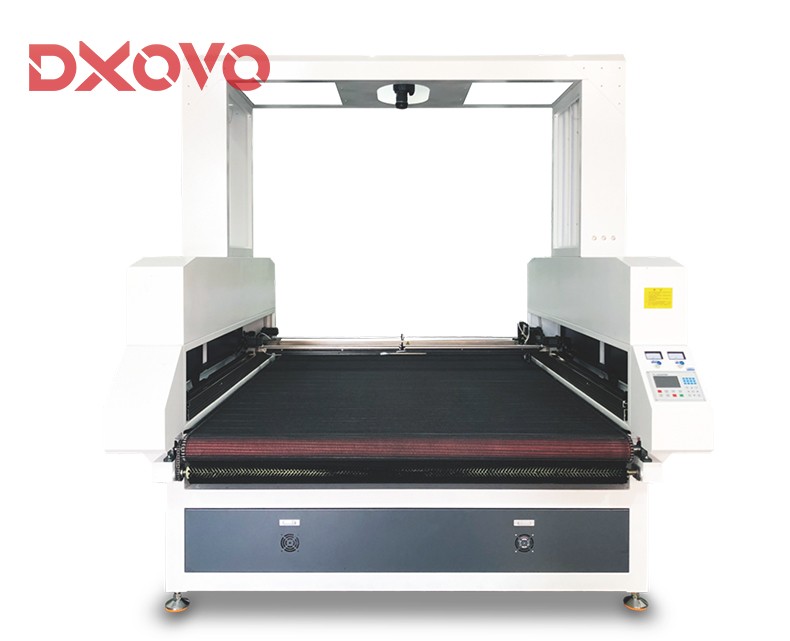

Textile digital printing machines have many innovative technologies and components in order to enable users to obtain a series of advantages. These parts are the main reasons for increasing the price of digital printing machines. Below, I explain what these components mean and how they affect the price of the device:

1. Nozzle

In order to greatly increase the speed and improve the printing quality, the digital printing machine uses many nozzles to accurately spray the ink onto the fabric. Hundreds of tiny nozzles on each printhead ensure that ink is ejected in very small droplets, resulting in high print resolution. Since extruders are an expensive component, the more extruders there are in a printer, the more expensive the machine will be. These nozzles are not included in the rotary screen printing machine, because the rotary screen printing machine needs to use nickel screen, and the nickel screen is not included in the cost of the rotary screen printing machine.

2. Ink technology and circuit control

In order for the printhead to work well, it must be driven by the correct ink supply technology and electronics. Ink delivery technology and electronics ensure that the printheads generate the correct resolution, eject small ink droplets onto the fabric as precisely as possible, and use the right amount and quality of ink to achieve a vivid and strong design. Therefore, the use of expensive ink supply systems and electronic components is why digital printing machines are more expensive than rotary screen printing machines.

3. Single or multi-pass printing

The cost of the machine will vary depending on the digital printing technology you choose. In a multi-pass digital printing machine, the nozzle moves from left to right across the fabric. Therefore, only a small number of spray heads are required to achieve the desired result.

If you choose a single-pass digital printing machine because you want more speed, then you will need more print heads. For example, the PIKE printer uses up to 258 print heads for unrivaled speed and amazing print quality. However, the large number of print heads means that the hardware cost of a single-pass digital printing machine can exceed 500,000 euros. Therefore, the price of the digital printing machine you choose depends on which digital printing technology you choose.

The following factors should also be considered before choosing textile digital printing equipment:

(1) Stamping cost. That is, comprehensive calculation of equipment depreciation, ink consumption, nozzle loss, factory rent, water and electricity costs, labor costs, etc., to calculate the comprehensive cost of printing finished products per square meter.

(2) The area occupied by the equipment and the required environmental conditions. It is necessary to measure the floor area required by the computing equipment and whether the temperature and humidity required by the environment are met.

(3) Water, electricity, gas and other requirements. It is necessary to understand the specific requirements of the power, voltage, air pressure, etc. of the equipment.

Solutions

Widely used in packaging, advertising, clothing, furniture, bags, footwear, automotive, aerospace, seal, energy, composite, etc.Contact Us

Business negotiation, looking for partners, Join Us.